Evaluation of different approaches for modeling phase transformations in machining simulation | SpringerLink

Manufacturing of cylindrical gears by generating cutting processes: A critical synthesis of analysis methods - ScienceDirect

JMMP | Free Full-Text | Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components | HTML

PDF) Increased tool performance with niobium carbide based cutting materials in dry cylindrical turning

Influence of the workpiece material on the cutting performance in low frequency vibration assisted drilling - ScienceDirect

What is faster? trochoidal cutting vs Bohren mit trochoidal / drill vs trochoidal / Cnc Milling - YouTube

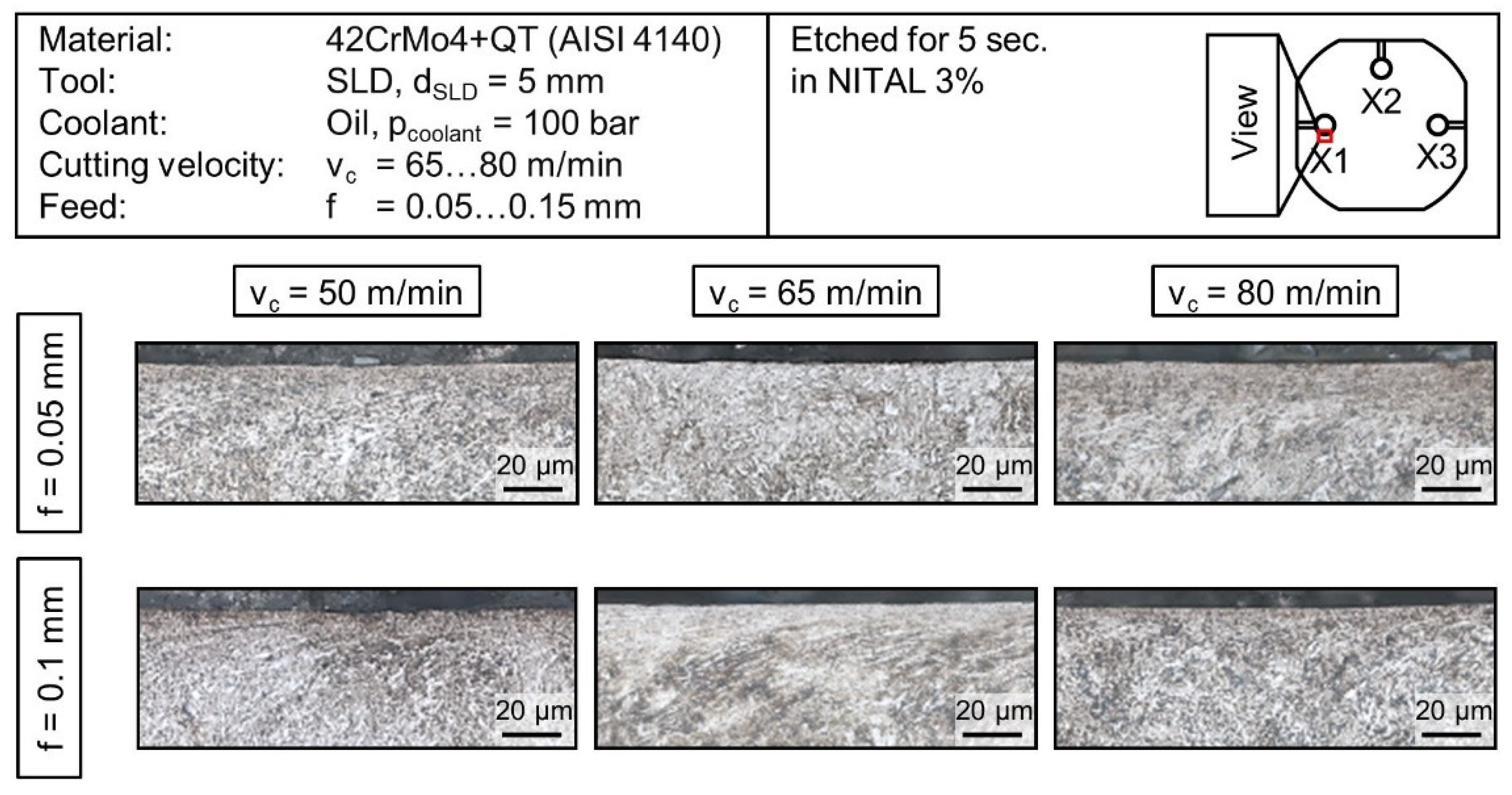

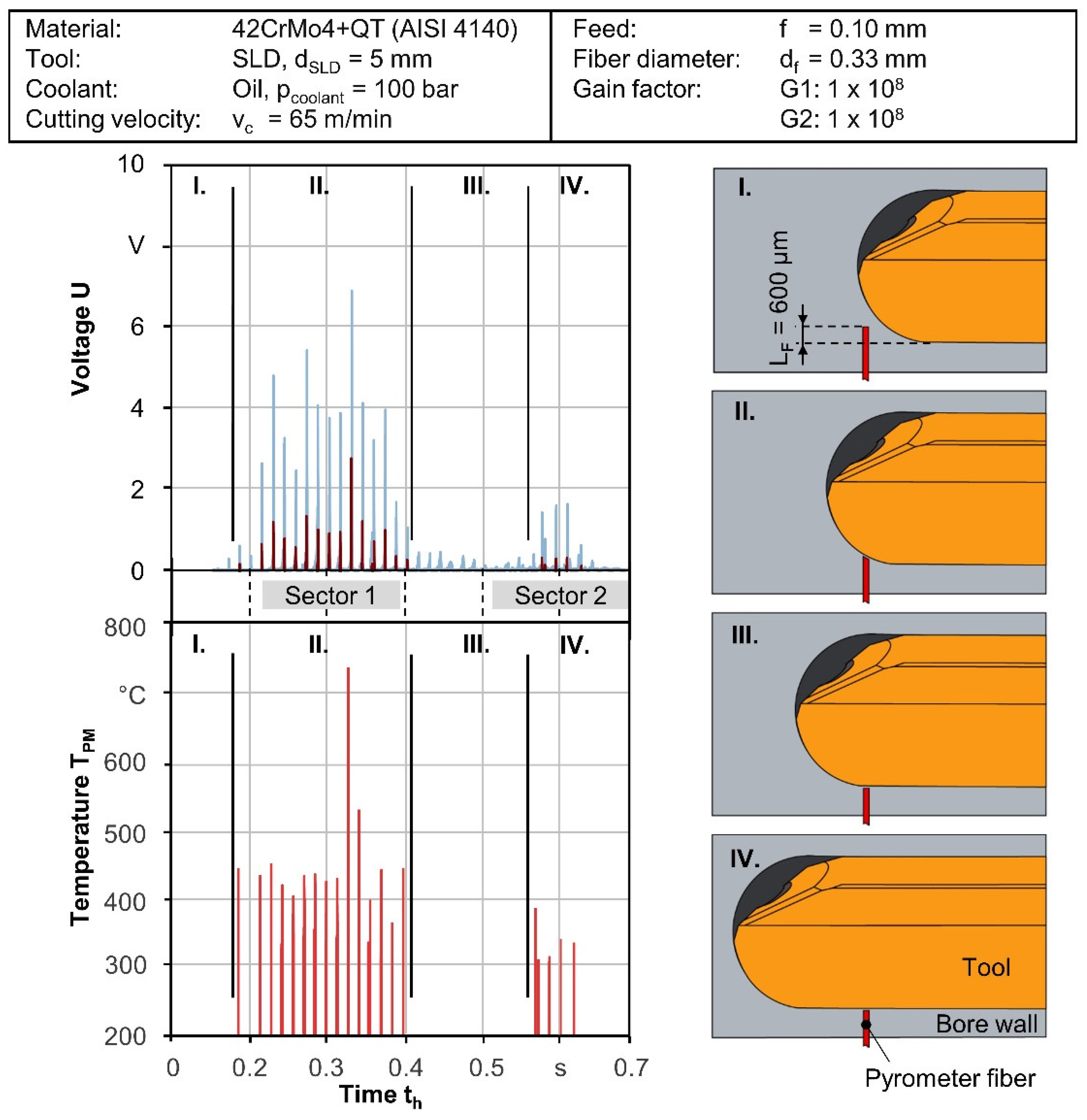

JMMP | Free Full-Text | Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components | HTML

PDF) Increased tool performance with niobium carbide based cutting materials in dry cylindrical turning

Influence of the workpiece material on the cutting performance in low frequency vibration assisted drilling - ScienceDirect

Influence of the workpiece material on the cutting performance in low frequency vibration assisted drilling - ScienceDirect

JMMP | Free Full-Text | Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components | HTML

JMMP | Free Full-Text | Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components | HTML

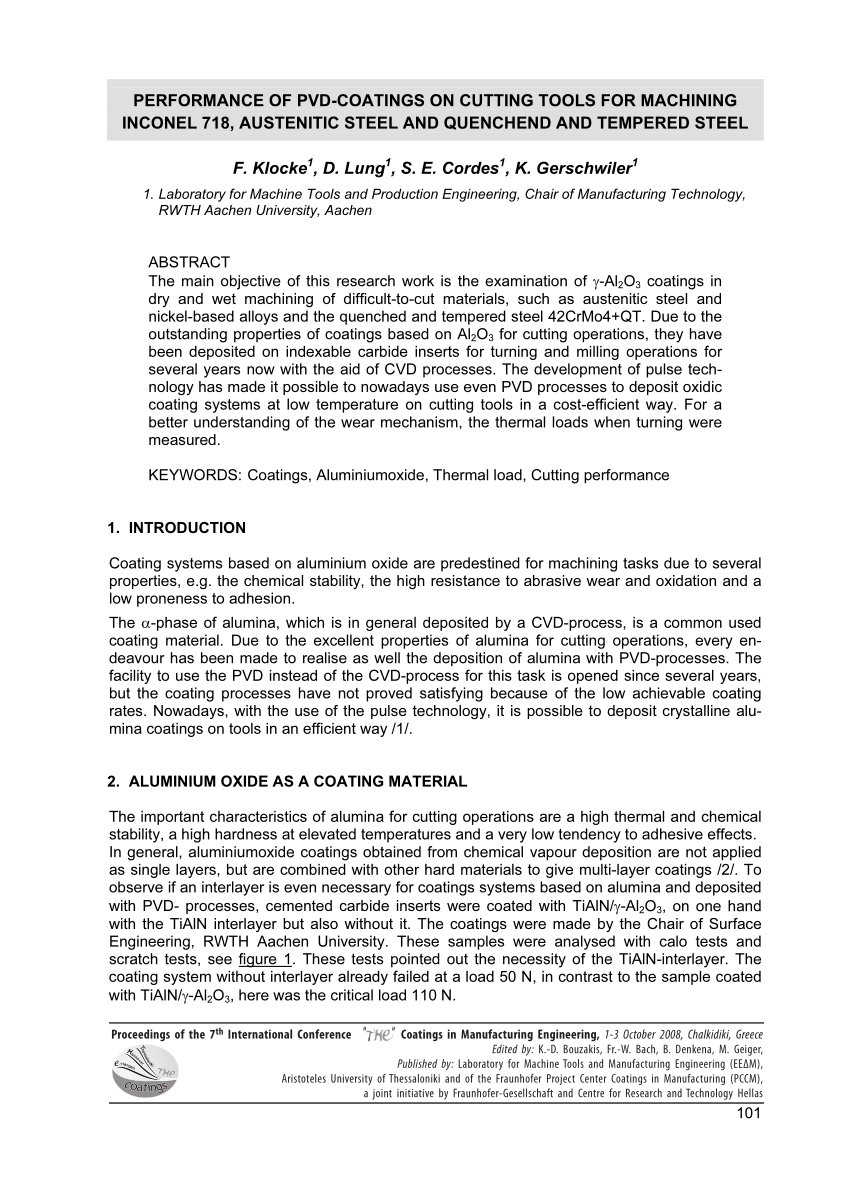

PDF) PERFORMANCE OF PVD-COATINGS ON CUTTING TOOLS FOR MACHINING INCONEL 718, AUSTENITIC STEEL AND QUENCHEND AND TEMPERED STEEL